Products

We have several standard packages available for immediate use. Packages can be adjusted according to the needs of each company.

Lean 5s Audits

Mobile application to answer questions related to the Lean 5s good practice criteria at the operation level. Free form or accessible via access code. Calculation of the final result obtained. Several automatic email notifications to the teams responsible for the areas evaluated. Consultation of forms by different filters.

See app video

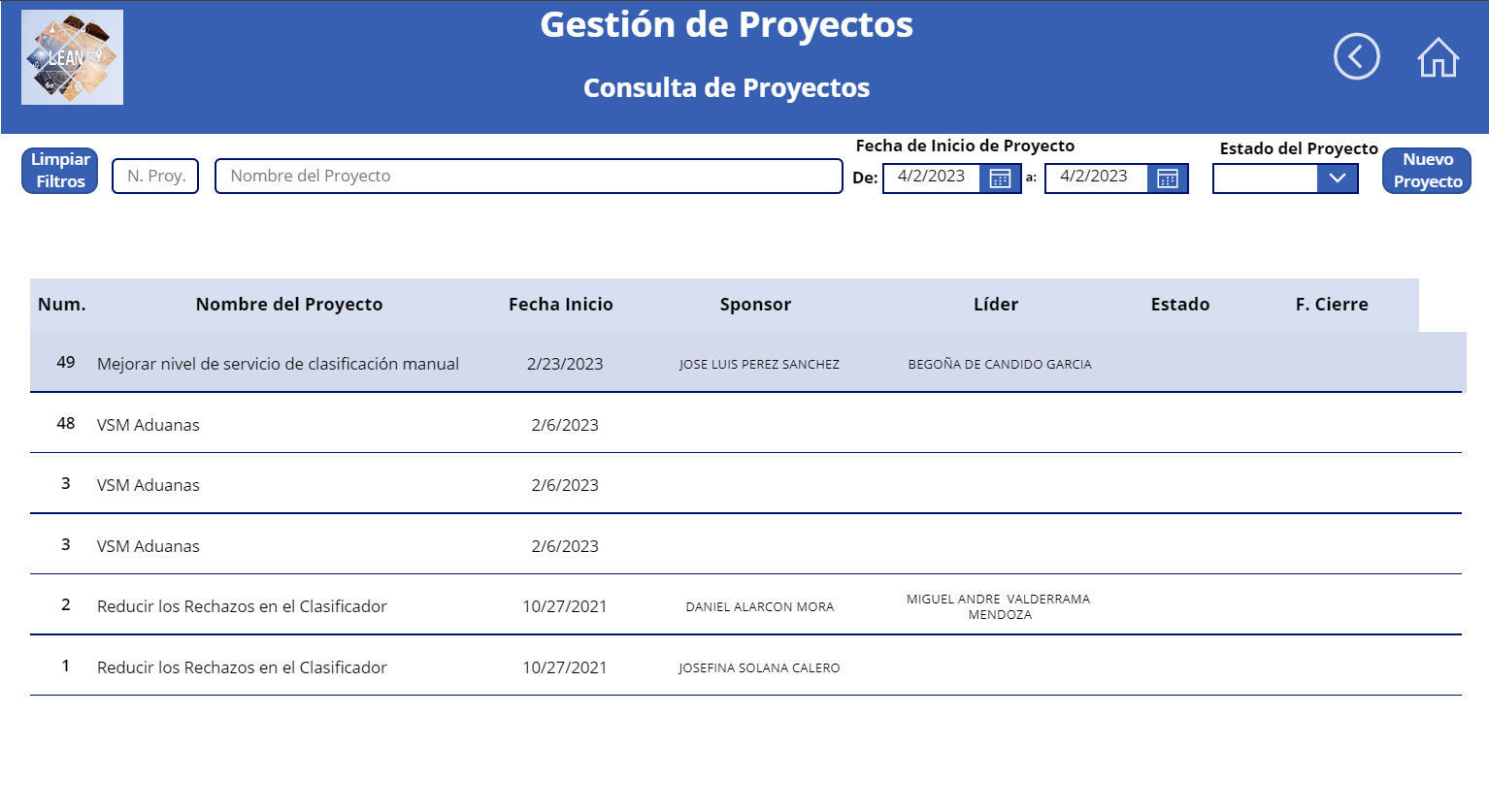

Project Management

App for managing projects from their charter, through the launch and control minutes with respective definitions of deliverables, until the project closure with the definition of actions and related benefits. Allocation of workload hours, as well as project risks.

See app video

Production

Application for production planning and registration. View up to 3 production lines simultaneously. Configuration of production lines based on product standardization. Definition of the product palletizing configuration.

See app video

Customer orders

Registration and editing of clients. Registration and editing of products. Registration and editing of customer orders. Customer order planning.

See app video

Bulk upload of products and their bill of materials

Automatic upload of the bill of materials and complete configuration of a product. CSV file uploaded to SharePoint that will be used by a PowerApps application for production and supply of materials.

See app video

Goods reception

Mobile application to record the receipt of merchandise at the operation level both by manual entry of the reference number and by reading the barcode. Record of the configuration of each merchandise when it is placed in the pack in which it is contained as palletized. Balance of receipt in relation to merchandise orders entered.

See app video

Goods storage

Mobile application to record the storage of merchandise at the operation. Possibility of manual entry of reference (with validation in the system of the registered merchandise) such as by barcode reading and balance of pending storage depending on the merchandise received and those already stored. Assignment of storage slot by reading the slot barcode to avoid data entry errors.

See app video

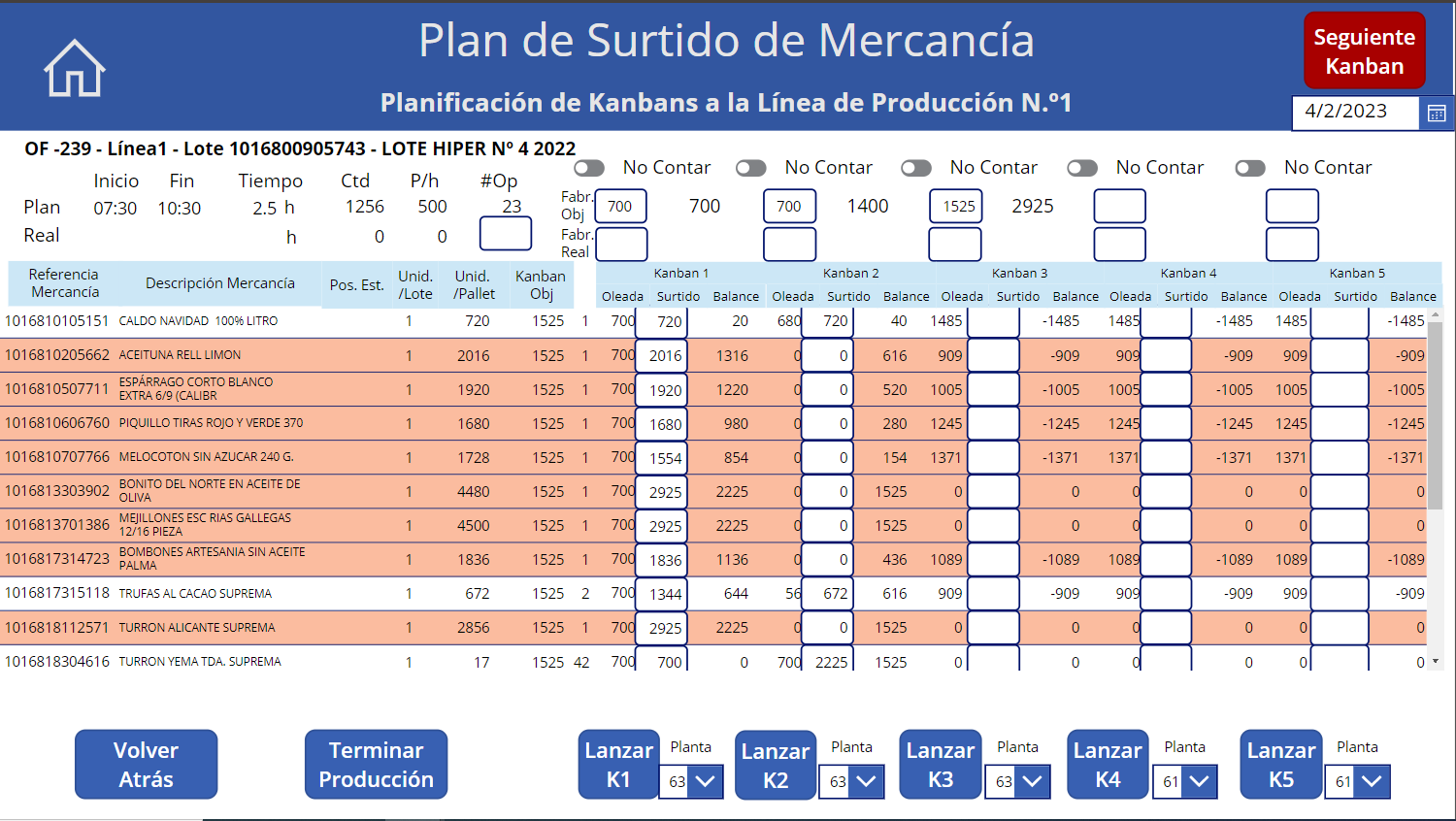

Goods picking in kanban

Establishment of Kanban objective and, based on the historical or estimated productivity of the production line, assignment of the quantities of materials to be consumed in each kanban period. Variable objectives depending on how production develops. Sending via Outlook an Excel file with the data structure to copy and paste into the master stock management system.

See app video

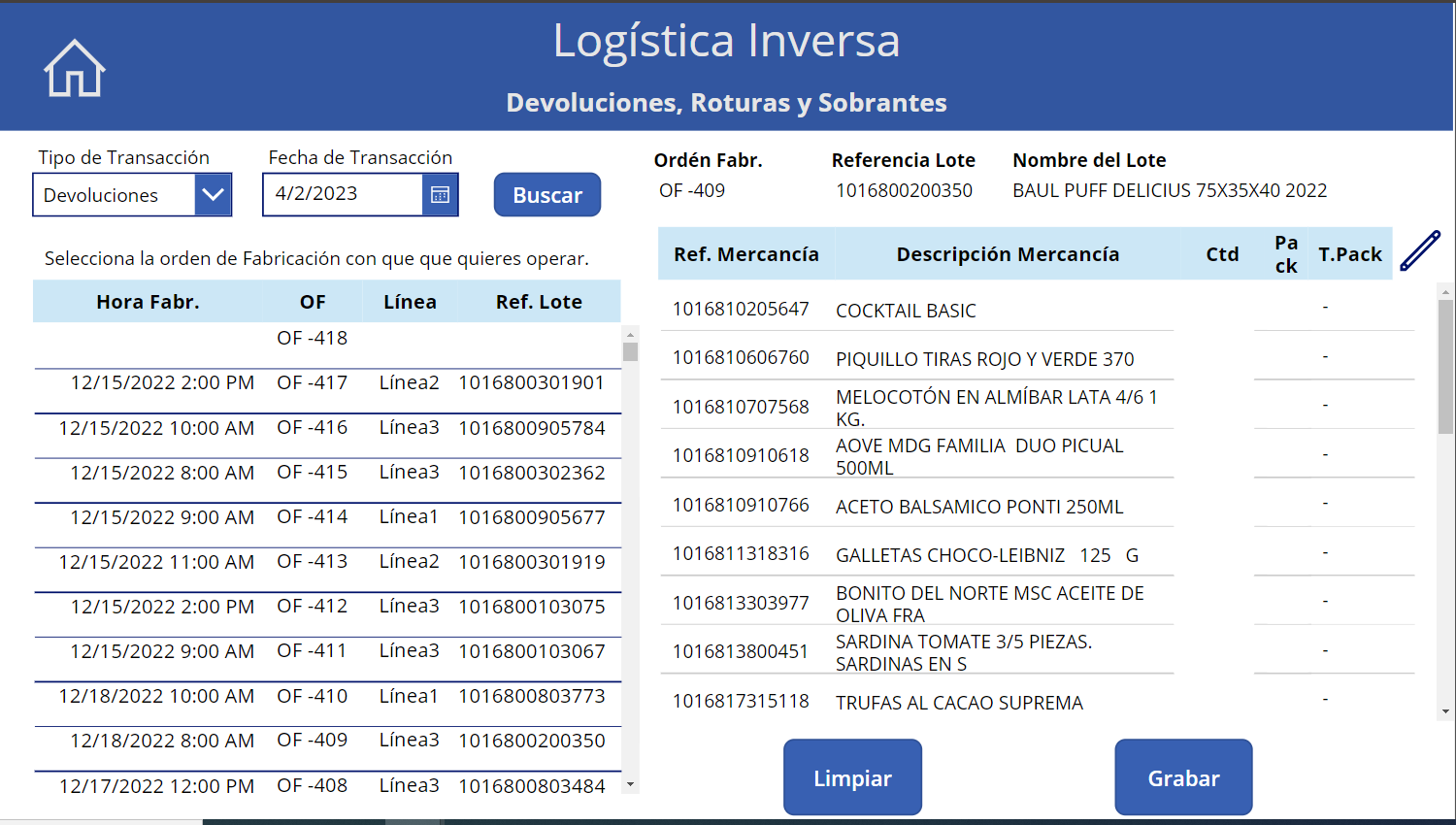

Reverse logistics

Mobile application to record all reverse logistics from production: Returns that will follow a claim to the supplier for poor condition; Breakage due to damage on the production line; and Surpluses from production that will be returned to the stock of raw materials.

See app video